Making Better Automotive Products Using 3D Technology

We specialize in 3D Scanning, Printing, and Development for Automotive Applications in Vancouver, BC Canada. We are very passionate about the automotive industry. Having both customized personal exotic cars as well as restoring multiple vintage classics. Our services were born out of solving our own problems. From accurate measurement for custom chassis development to building perfectly fitting custom pieces, we love doing this because we use these same processes in our own car builds.

What 3D Scanning enables

Parts Replication

Motion Analysis

Vinyl Wrap

Virtual Assembly

Custom Chassis

Body Bucks

Reverse Engineering

Custom Parts

Scale Models

Prototyping

Comparison

Archive

3D Scanning

From indivdual parts, engines, interior, or entire cars it can all be scanned. We do this onsite at your shop as the ideal conditions are indoors and out of the sun. Our scanners are very accurate from 0.045mm to 0.1mm.

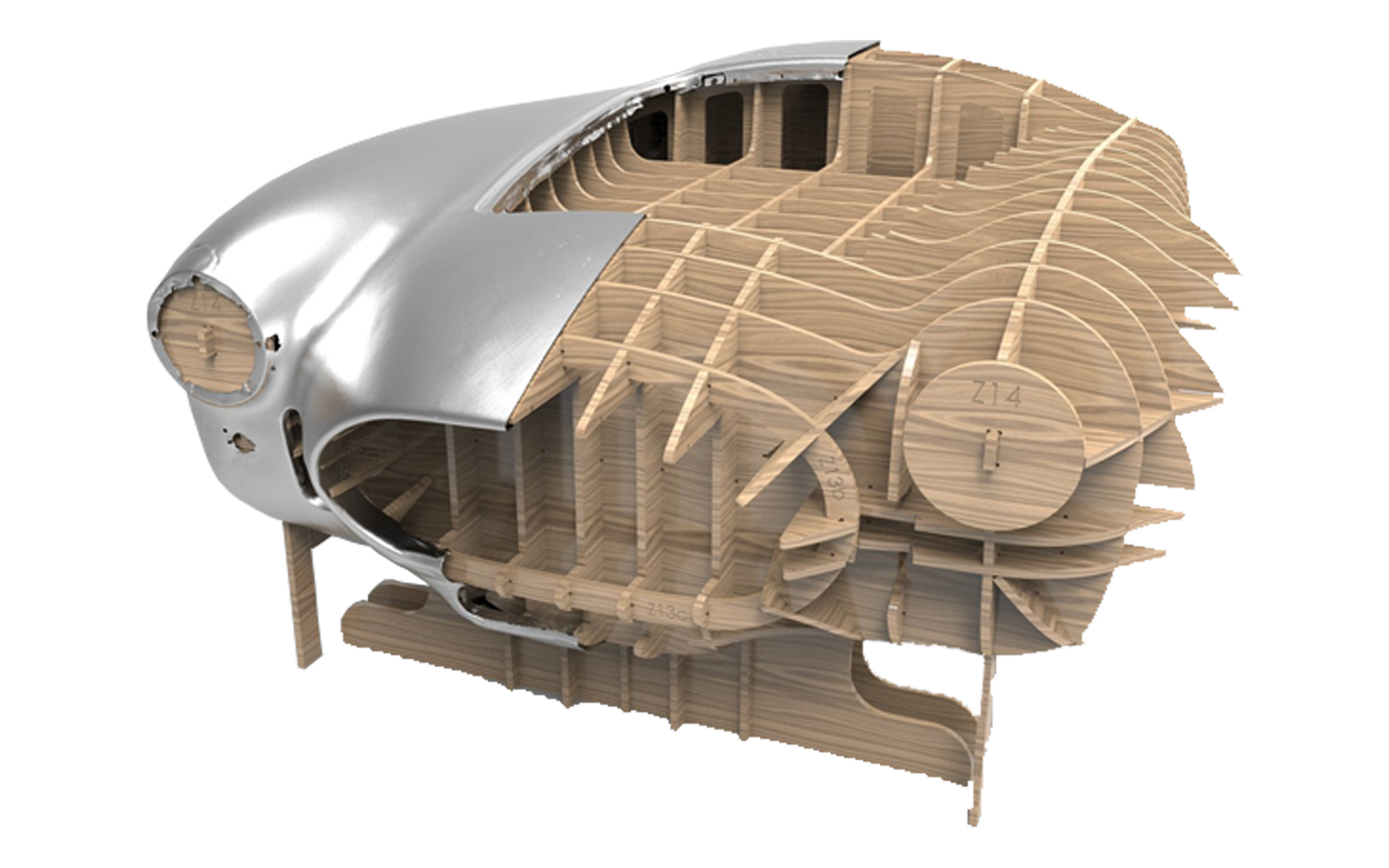

Body Bucks

Scan part or all of a car for replicating sheetmetal components using body bucks. We can develop these bucks for you in 3D and you can have them cut from MDF board with a CNC Router.

Custom Parts

Scan a dash or other area of a car and develop a custom part that fits perfectly, adds a custom design, and will fit as factory.

Chassis Design

We can scan the chassis of your classic car with precise measurements for your chassis developer to work from. We can also scan your body once off the frame so your chassis developer can ensure proper fit, alignment, and suspension travel without conflict.

3D Printing

Save yourself the high costs of testing custom parts in materials such as billet by producing a part in plastics first. We can print custom parts to be test fit and design reviewed first before sending to a CNC mill.

Print twice, make once

Having parts made in billet aluminum or carbon fiber can be very expensive. Printing these parts first in plastics to ensure a perfect fit and correct design can save these costs. Make sure the parts are perfect before sending them off to the expensive processes.

Replicate the Impossible

Need to make a copy of that impossible to find switch from a 300SL? Once a part has been scanned we can print parts in ABS or Polycarbonate to have high strength and heat resistance. These parts can be traditionally painted or done in a modern chrome paint.

Scale for fun

Have a radical custom car that gets stored for the winter? Want a reminder of your fun toy on your work desk? We can scan your entire car with all the custom features and print it for you in a scale form. We can even print in shinny gold and silver colours!

Our Process

Plan and Scan

We plan out the project together to determine what needs to be 3D scanned.

Design

We design any custom parts, body bucks, or other components for you or with your team.

Refine

We work iteratively with you and your team to ensure the best design and fit.

Build

In most cases we can first build the custom parts for you on our 3D printer prior to milling.

About Me

Hello! I’m Aaron. I’ve Been Building Tech and Cars for 20 Years

I’ve had a passion for building cars since I was 19 years old with my first hot rod – a 1957 Chevrolet Sedan Delivery.

My pursuits in my career took me into technology where I have worked on many projects building technology, doing graphics design, and starting multiple companies.

Alsop Design became born from solving my own problems. It started with wanting to make custom switch panels for my 1932 Ford Roadster project. Then it was fuelled by a need to create detailed measurements of a 1956 Ford Parklane chassis for a chassis designer.

The ability to merge my passion for technology by leveraging 3D scanning and modelling with my passion for building very cool cars seemed ideal. I’m very excited to help you build your next project!